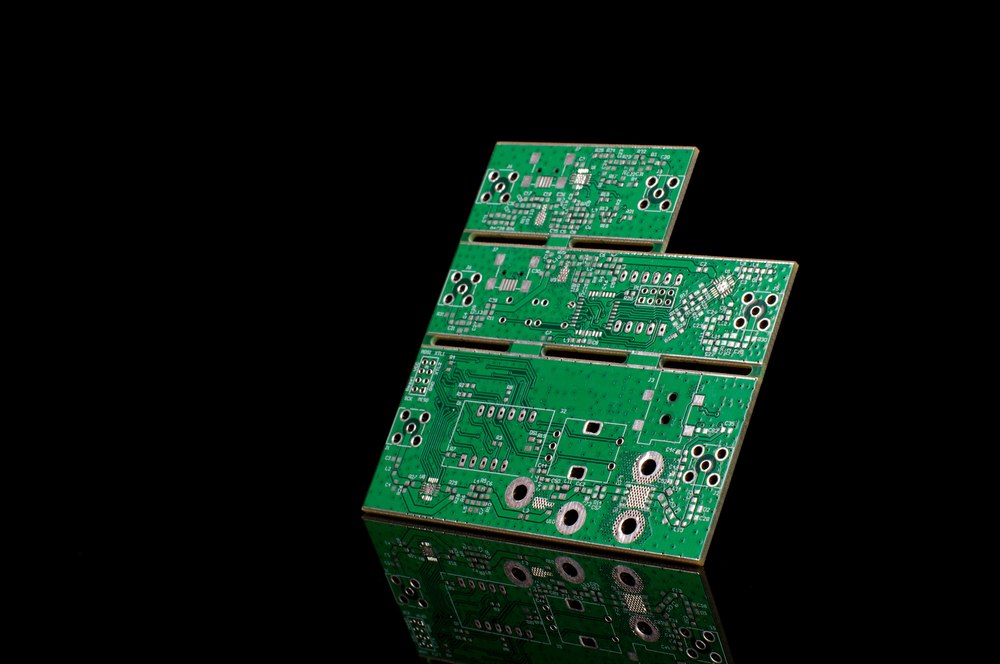

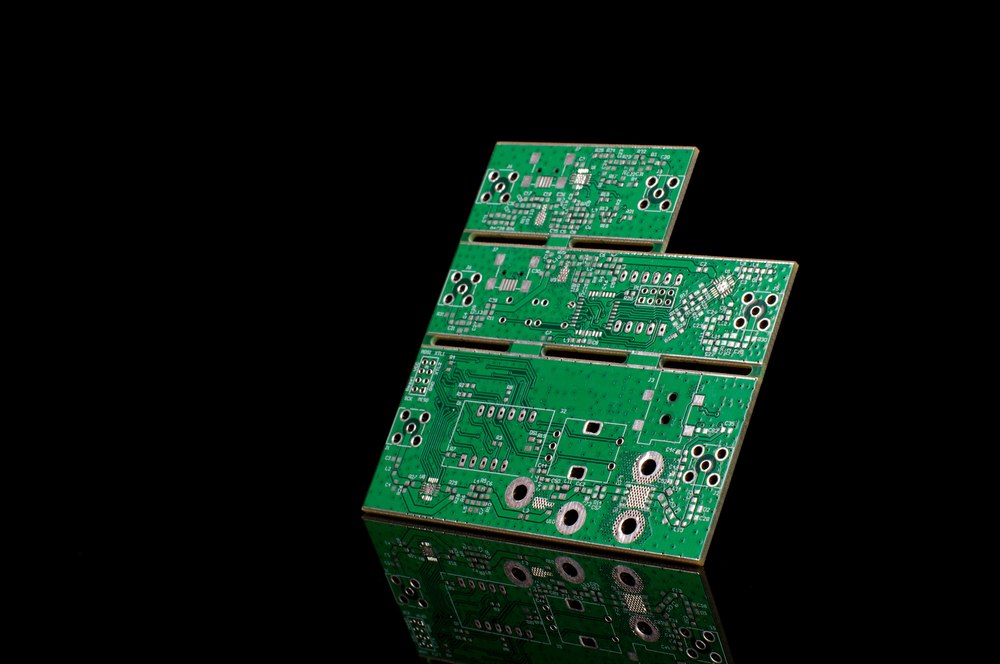

There are many demanding deliberations based on the plan for the level of production volumes and type of production in the PCB assembly project. To make sure that no criteria are overlooked and missed upon, we scrutinize and analyze all the aspects of your PCB projects. Our flexibility to use human resource and machines with moderate technologies proves our reliability to load the project at the right time and economy.

We have adopted flexibility to provide prototyping services with full or partial turnkey assembly wherein the components and all the inputs needed in the PCB manufacturing as per the specifications in the BOM and Gerber File are being arranged by us fully or partially.

Our core focus is to give optimal cost effective inventory management services with a dynamic approach to utilization of manpower and machine as it is totally dependent on the low or high run production with accurate results. Our global outlay has made it possible to adopt an effective procurement process of the components used in the PCB production to toss around the ease and difficulty in obtaining those components.